Innovation

Home![]() Innovation

Innovation

সাসটেইনেবল এন্টারপ্রাইজ প্রজেক্ট- এসইপি’র আওতায় বাস্তবায়নাধীন উপ-প্রকল্প ‘‘সিরাজগঞ্জ জেলার তাঁত উদ্যোগে পরিবেশগত সমস্যাসমূহ বিবেচনায় রেখে গুণগত মানসম্পন্ন ঐতিহ্যবাহী বাঙ্গালী পোষাকের উৎপাদন বৃদ্ধি প্রকল্প” এর তাঁত অধ্যুষিত এলাকায় বাস্তবায়িত পিট সম্পর্কে ধারনা।

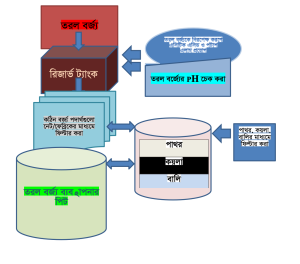

পিট হচ্ছে তরল বর্জ্য ব্যবস্থাপনার এমন একটি প্রক্রিয়া যা স্বল্পমাত্রার ডাইংয়ের তরল বর্জ্য ব্যবস্থাপনার জন্য বিশেষভাবে নকশা করা হয়েছে। যার মাধ্যমে তরল বর্জ্য পদার্থ কয়েক ধাপে প্রক্রিয়া করে তাতে উপস্থিত ক্ষতিকারক ভারী রাসায়নিক পদার্থগুলো ফিল্টারেশনের মাধ্যমে আটকিয়ে পানিগুলো বিশেষ গর্তে ছাড়া হয়।

পিটের কিছু বৈশিষ্টঃ

এটি সম্পুর্ন স্থানীয়ভাবে উদ্ভাবিত প্রযুক্তি।

এটি স্বল্প খরচে স্থাপন করা যায়।

এসইপি’র আওতায় বাস্তবায়নাধীন উপ-প্রকল্পসমূহের মধ্যে সিরাজগঞ্জ জেলার তাঁত উদ্যোগে সর্বপ্রথম এটির প্রয়োগ ঘটে।

এতে কয়েক স্তরের ফিল্টারেশনের ব্যবস্থা রয়েছে।

তরল বর্জ্য ব্যবস্থাপনা পিটের মডেল

পিটের পানি প্রক্রিয়াতরণ করার উপাদানসমূহঃ

পটাশ এলাম (ফিটকিরী), এসিটিক এসিড

বালি, পাথর, কয়লা

নেট/ফেব্রিক ইত্যাদি।

পিটের মাধ্যমে তরল বর্জ্য ব্যবস্থাপনা প্রক্রিয়াকরণের মডেল

কর্ম এলাকায় পরিলক্ষিত সমস্যাসমূহঃ

বর্জ্য ব্যবস্থাপনার জন্য পিটের গুরুত্ব উপলব্ধি না করা।

স্থানীয় লাগসই প্রযুক্তির অভাব পরিলক্ষিত হয়।

যথাযথ রক্ষণাবেক্ষণে অনীহা।

Mini-ETP

Mini ETP (Effluent Treatment Plant): An invention of NDP SEP-Loom to Protect Environment in Loom Cluster

With the technical assistance of PKSF & financial support by World Bank, National Development Programme (NDP) is implementing “Improving the Quality of Traditional Bengali Clothing by reducing environmental consequences of Loom enterprises in Sirajganj” sub project Under Sustainable Enterprise Project (SEP) in Sirajganj Sadar, Kamarkhanda and Belkuchi upazila of Sirajganj district. The sub-project activities are being implemented in the business clusters of “Loom” subsector to improve the overall business and environment of the microenterprises.

Waste water management is a great concern to protect environment in loom cluster. There are about 275 dyeing unit in the project working area which generate 1000 Liter waste water per day averagely. This huge waste water is discharged directly nearby water bodies or open space without taking any precautionary measures.

The environmental impact of discharging waste water into nature is devastating. The surface and ground water are being polluted seriously for this indigenous bad practices of the MEs (micro entrepreneurs.) Because of this the pregnant mothers & new born babies are sufferings from various water borne diseases in the loom cluster. It seems the reason of highest concentration of the babies with disabilities is at Tamai village for water pollution. In spite of existing serious water pollution there is no possible solutions to prevent dyeing related pollution in the loom cluster.

The ETP is the ultimate solution to manage waste water but the structure of dyeing unit in the loom cluster of Sirajganj & the financial capacity of dyeing ME are not feasible to install ETP. UNDP tried to install a central ETP for Tamai village but due to existing various social & local political influences the ETP is now abandoned & the water pollution is continuing without taking any measures.

Considering the all existing barriers NDP SEP-Loom unit was searching a sustainable solution to manage the dyeing waste water with the full support of NDP management. Mr. Asrafuzzaman team leader & the project manager of NDP SEP-Loom engaged himself to study different relevant documents on low cost waste water management technology. He communicated with concerns to find out a probable sustainable solution to design a low cost waste water management plant/ETP. Moreover, Mr. Asraf communicated with the experts and different government & non-government organizations who work to manage waste water. But unfortunately nobody was able to provide any solution in this regard. Mr. Asraf works hard for one and a half year and develops mini ETP concept with the help of Exceptional Environmental Engineering (An engineering firm of water, power & construction solutions). We are hopeful that mini ETP will be feasible for the loom cluster to manage waste water.

The design of mini ETP was shared with the relevant experts & organizations. All of the relevant experts and organizations are very optimistic about the result of mini ETP.

During the development of the concept of Mini ETP Mr.Asraf was searching interested ME for the installation of mini ETP in the loom cluster for the first time.

Though it’s mini ETP but total cost will be more than 7 lac taka that is huge for an individual ME to invest just for the protection of environment without any business benefits. NDP SEP-Loom selected 5 MEs primarily by whom mini ETP would be installed. It was very challenging to convince the selected ME to install the mini ETP. Through a series of meetings and motivational sessions Mr.Anowar a dyeing unit owner of Tamai village agreed to install the mini ETP in his dyeing unit premises finallay. On behalf of Mr.Anowar NDP SEP-Loom made an agreement with Exceptional Environmental Engineering (An engineering firm of water, power & construction solutions) to bring a revolutionary changes in loom cluster to manage waste water.

All the features of the mini ETP & the information of the installation mini ETP have been disseminated among the stakeholders by arranging a lesson learning workshop at Belkuchi UNO office. Mr.Anisur Rahman, UNO of Belkuchi Upazilla who was chief guest in the workshop said, “Waste water management is a great challenge in Belkuchi Upazilla but Upazilla administration cannot take proper legal action considering the huge investment to manage waste water.” He added, “I also thought about the low cost sustainable solution for dyeing waste water management but nobody provide me solution on it.” He thanked NDP SEP-Loom unit to develop the mini ETP concept. He expressed his wishes for the success of mini ETP. He said again, “If the mini ETP brings expected result, Belkuchi Upazilla administration along with DoE will take initiatives to install the mini ETP in each and every dyeing unit to protect and preserve the environment in loom cluster.”

The installation works of the mini ETP has already been started at the dyeing premises of Mr.Anowar.

A hats off salute to Mr.Anowar who has taken the risk and invested more than 7 lac taka to install mini ETP for the first time by taking common service loan from NDP credit support programme. Mr.Anowar and NDP SEP-Loom have jointly take the calculative risk to start the environment protection revolution in the loom cluster. NDP SEP-loom does believe that the first successful installation and trial of mini ETP will definitely bring improvement in the field of dyeing waste water management. No pregnant mother will fear to give birth disable babies in the loom cluster due to drink the contaminated ground water. So, we can say. “Mini ETP: A Small Initiative but a Great Innovation to Protect Environment in Loom Cluster.”

Md.Asrafuzzaman

Project Manager (NDP SEP-Loom)

Natural Dyeing

NATURAL VEGETABLE DYE

Natural dyeing is the only process of dyeing which is known as eco-friendly. To reduce pollution and to expose eco-friendly market NDP-SEP (Loom) project has done hard work with it.We have provided trainings to our ME’s about natural dyeing,product diversification and machine maintenance and modification to skill up.Finally some of our ME’s are still working with it.

Natural Vegetable Dyes For Fabric Are Dyes Or Colourants Derived From Natural Sources, That Is, Plants, Animals, Fungi And Minerals. It Is Mostly Derived From Plants Sources. These Can Be Different Parts Of The Plant Like Root, Stem, Leaves, Bark, Berries, Etc. Many Natural Dyes Require The Use Of Substances Called Mordants To Bind The Dye To The Textile Fibres. Natural Dyes Work The Best On Natural Fibre Materials.